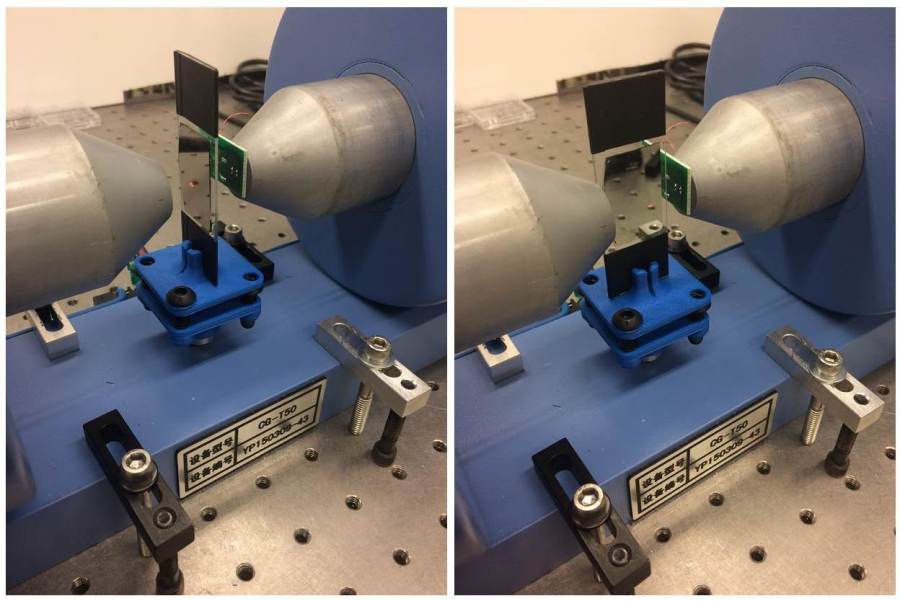

Bi-Axial MOKE Measurement Stage

I designed and 3D printed this stage for making repeated Magneto-Optical Kerr Effect measurements in both Polar (left) and Longitudinal (right) orientations. Magnetic thin films grown on silicon wafers are temporarily attached to a microscope slide. The slide is then inserted into the base in the desired orientation. The screws in the front right and back left allow the stage to pitch back and forth on two orthogonal axes. This provides all necessary adjustment when switching between samples or orientations, allowing the laser source and the detection device to remain fixed in place. This design significantly reduced set-up time between consecutive MOKE measurements in our lab, and allowed me to collect all of the data for my 2016 FRAMS poster in less than a week!

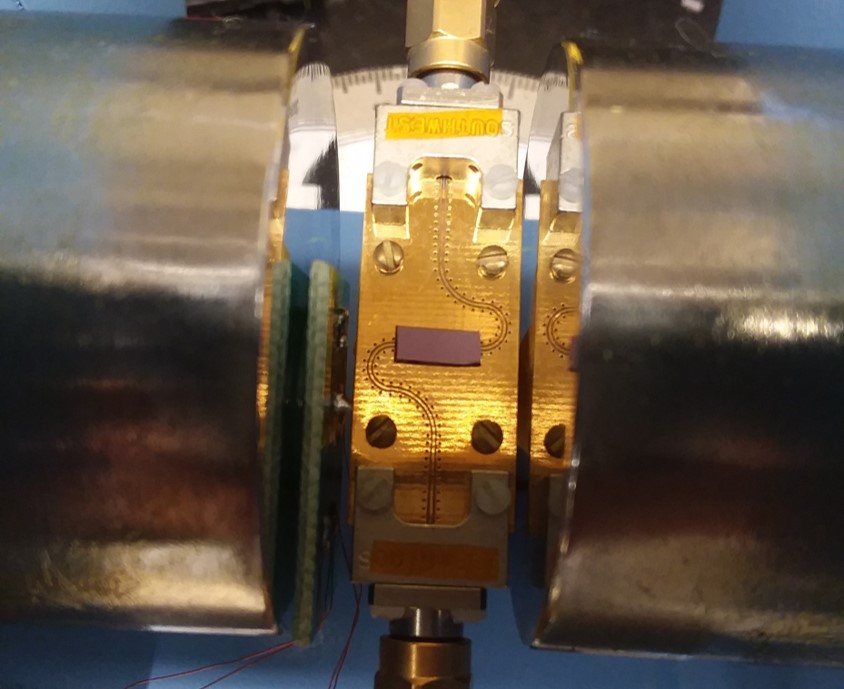

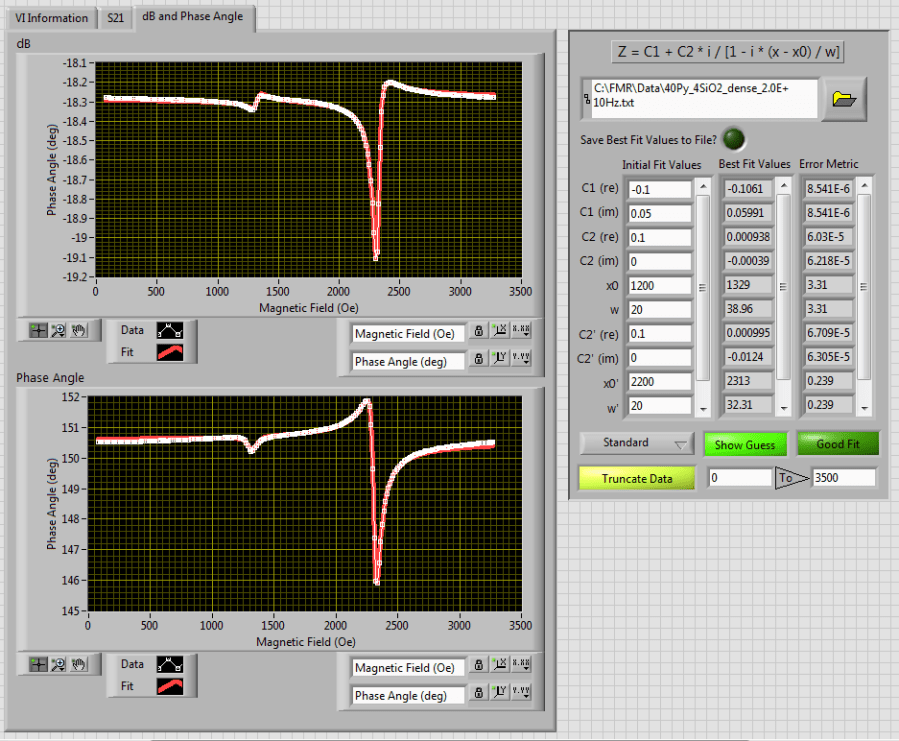

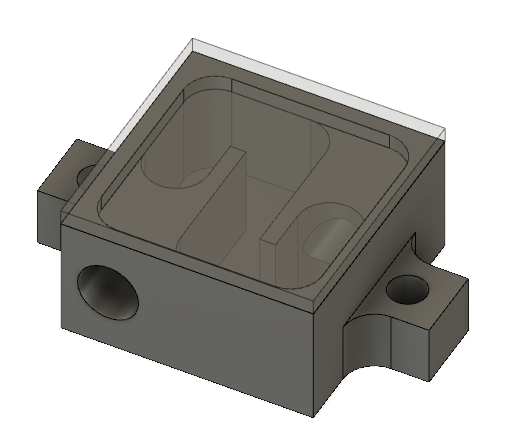

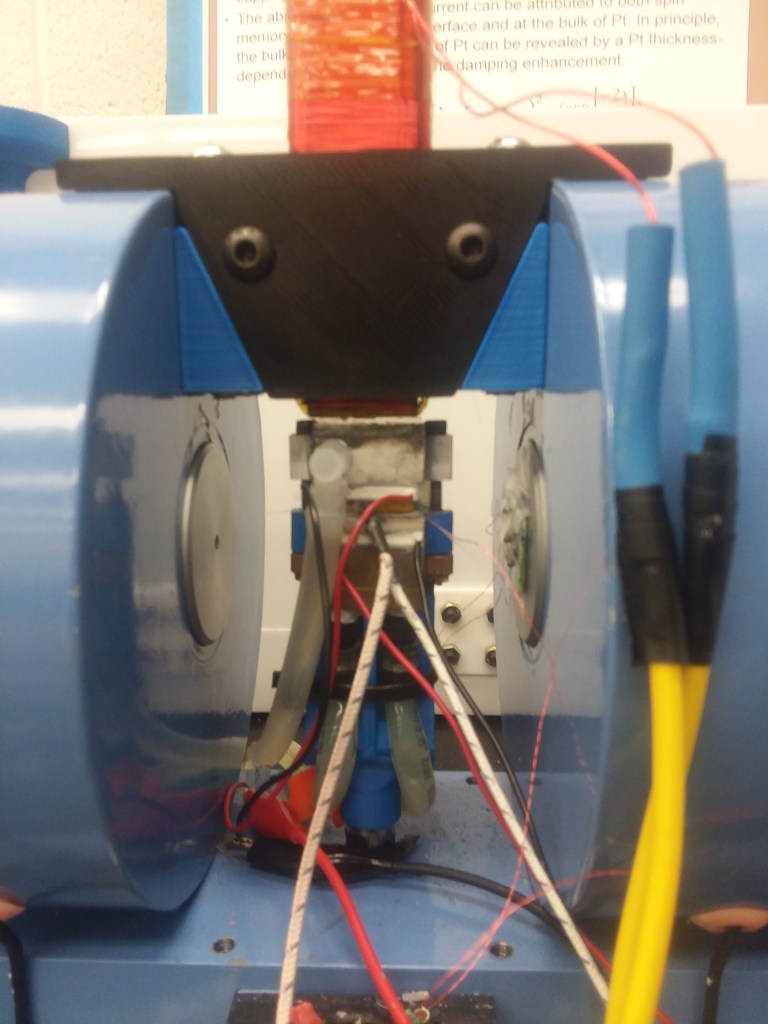

CPW-FMR Measurement Apparatus

Over the summer of 2018 I designed and assembled a complete system for conducting Ferromagnetic Resonance measurements with a coplanar waveguide. I 3D printed a fixture to hold the CPW between the poles of an electromagnet, and to reduce stress on the cables carrying the microwave signal. I also coded LabVIEW programs to control the measurement and to fit the complex data using the Levenberg-Marquardt algorithm. Fitting the data to a complex function (rather than splitting it into real and imaginary components) requires fewer unknown variables and consequently produces a more accurate fitting result.

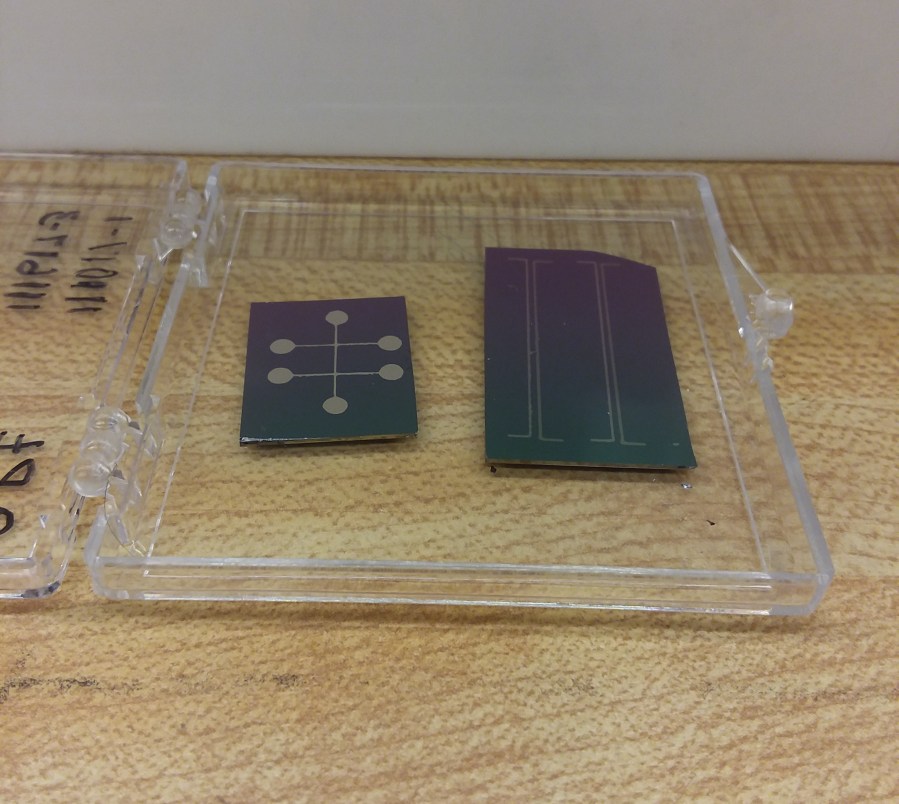

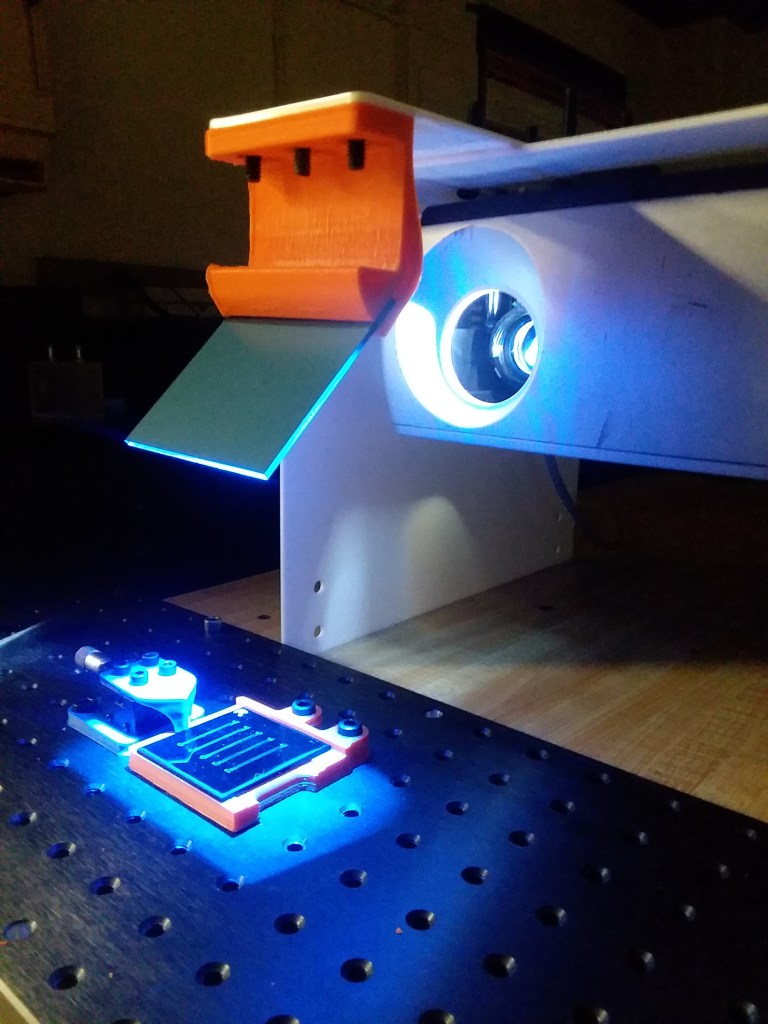

Projector Photolithography Apparatus

For many tests our lab conducts, it is necessary to use photolithography to pattern samples before deposition. These patterns can be made incredibly small with advanced manufacturing techniques, but often times millimeter scale patterns can be useful as well. Instead of relying on a professional manufacturer to produce large patterned samples for us, we’ve managed to replicate the entire process in our lab. This has saved us hundreds of dollars and countless hours between prototypes, and allows us to modify parameters and observe same day results.

We use a retired classroom projector as our light source, and a combination of laser-cut acrylic and 3D printed parts to elevate it above the exposure stage and direct the light downwards. These rapid manufacturing processes are relatively easy to get started with, and have allowed us to significantly improve both the look and function of our lab. The array of tapped holes on the table allow us to fix custom-made alignment components to the surface, such that repeated exposures will be under near identical conditions.

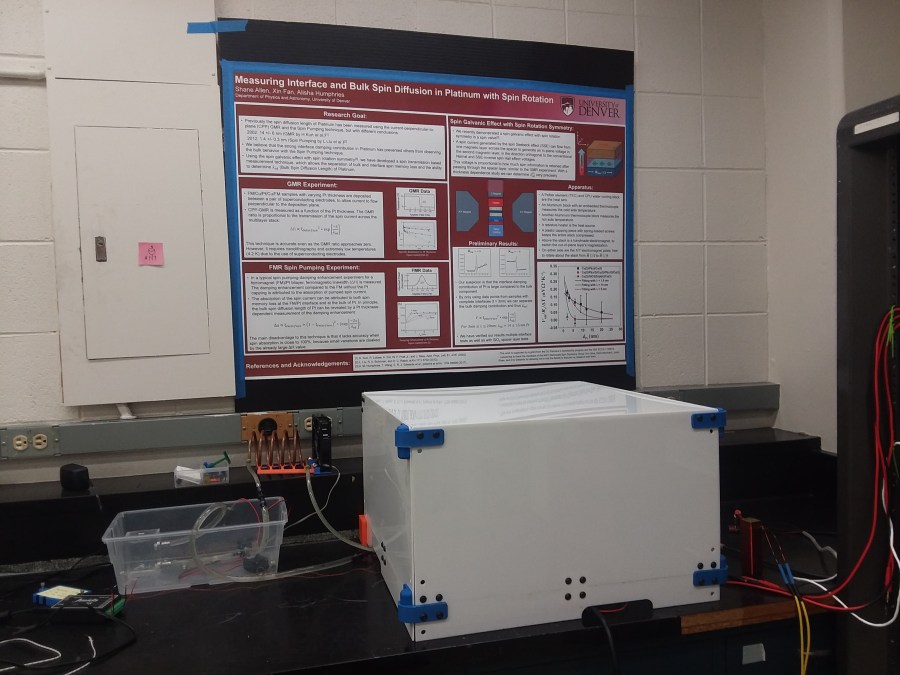

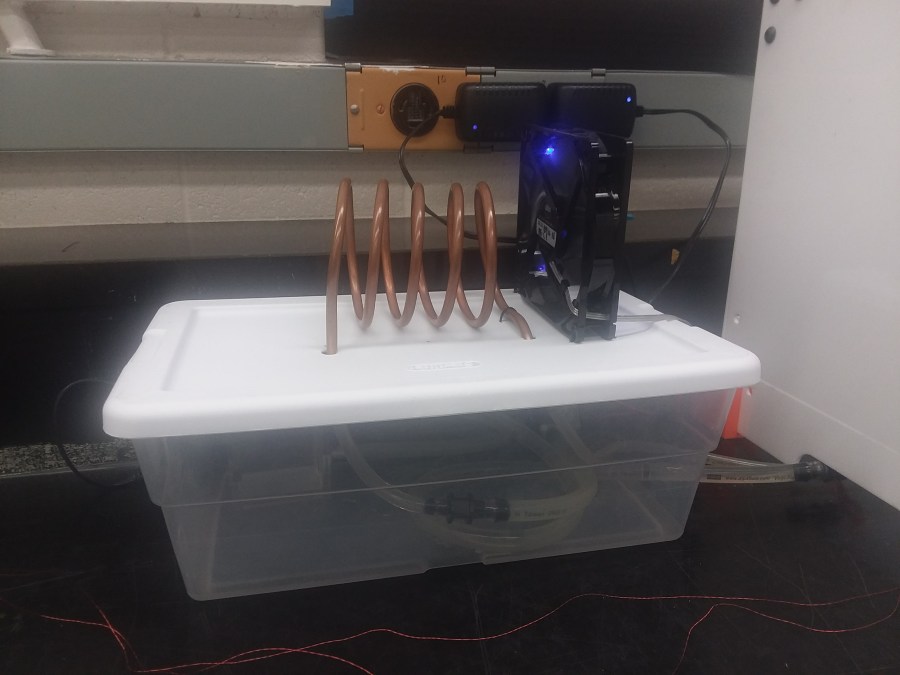

Magneto-Thermo-Electric Measurement Apparatus

With this device we have the ability to measure the electric behavior of a thin film samples while manipulating a variety of conditions:

- In-plane magnetic field, with 360 degrees of rotation and programmatically controlled magnitude

- Perpendicular-to-plane magnetic field with programmatically controlled magnitude

- Perpendicular-to-plane temperature gradient